- USABoston

- UKGlasgow

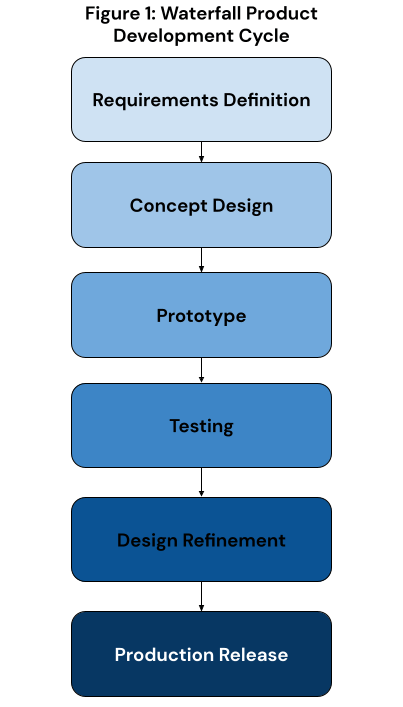

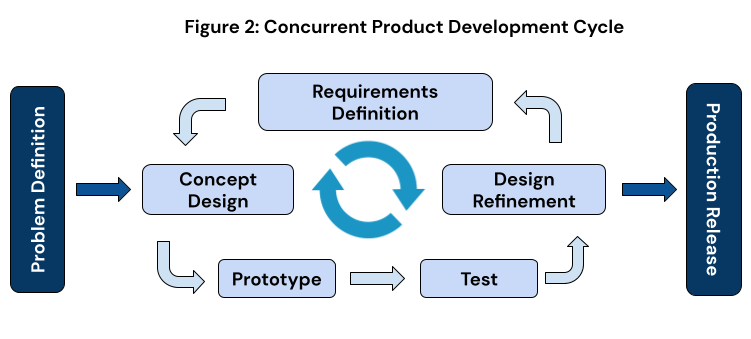

The traditional approach to engineering was to follow a sequential design process, known as the “waterfall” method [Fig 1]. Projects following this workflow often encounter delays as the creation of a physical prototype acts as the gate-keeper to product completion. Modern engineering methods have evolved towards a concurrent design philosophy [Fig 2], which employs the simultaneous development of design, prototype, requirements, and manufacturing. Prototypes provide a real-world understanding of ergonomics, aesthetics, function, accessibility and manufacturing. One of the key elements of the concurrent design workflow is rapid prototyping to quickly test variations and gain a better understanding of the challenges of the project. These are 5 strategies for rapid prototyping that MACABItech utilizes:

Rapid prototyping technology has garnered worldwide attention with the recent easy access to desktop 3D printers, open source digital router designs and free access to CAD/CAM software. As a result, rapid prototyping has been adopted in a variety of cutting edge industries, particularly in the area of product development and prototype manufacturing.

Current rapid prototyping technology allows companies to rapidly iterate between

tangible artifacts created directly from three dimensional CAD data from a wide variety of materials, including polymers, metals and composites.

To remain competitive in the current marketplace, product designs must be offered in a large number of variants, containing a multitude of functions, and be delivered within the shortest possible time. Therefore, rapid prototype design and development of new components is of the utmost importance.

Perhaps one of the most valuable benefits of rapid prototyping is the ability for design teams to quickly create parts that can be interacted with. Physical interaction can massively accelerate the comprehension of complex features and operations. Furthermore, these prototypes can be used to convey design issues to key stakeholders, many of whom may not have the same level of technical comprehension as those in the design team.

Agile iteration is a crucial component of design optimization. Previously, the development of a prototype required a multitude of costly labour intensive processes, such that little to no time could be spent on design iteration. MACABItech’s modern approach to prototype development means that models can be quickly redesigned and retested, meaning that the design process never stagnates.This process, in combination with our expert engineering analysis, can often lead to a substantially improved design solution after only three or four iterations.

Optimization, like iteration, can be a costly and time intensive process that seeks to improve both qualitative and quantitative metrics to the satisfaction of key stakeholders. After a design has been functionally approved, optimization begins. This part in the design process is usually necessary as the likelihood that designers and engineers will have met all parts of the Product Design Specification on the first attempt is very small. A huge advantage of rapid prototyping is that it allows the design team to investigate a multitude of designs without incurring severe cost or time penalties. When a functional design is achieved through successive iteration, one has the opportunity to attempt to optimize the design. Since prototypes are generated rapidly, a range of test models that might have previously taken significant resources and time to create can now be completed in weeks. The optimization process can explore the sensitivity of specific metrics to a number of variations, such as changes in weight, strength, or ergonomics. This is useful information which sometimes results in a decrease in cost through material reduction, manufacturing refinement, or decreased part count.

Another important benefit of rapid prototyping technology is the facilitation of Concurrent Engineering which has become a most powerful and useful project management structure in design and product development. Concurrent engineering is a method of designing and developing engineering products, in which different departments work on the different stages of engineering product development simultaneously. If managed well, it helps to increase the efficiency of product development and marketing considerably, reducing time spent and contributing to the reduction of the overall development cost while improving the final product quality.

Very few technologies have offered as much to design teams as rapid prototyping technology. Components can now be produced in a fraction of the time that was required previously with a host of added benefits including; reduced costs, more design iterations, concurrent designing and improved design optimization.

Luckily, advances in rapid prototype technology has allowed engineering firms to continue working during the COVID-19 pandemic. The ability to have small 3D printers, routers and similar benchtop processes, has meant that many designers and engineers can share low fidelity artifacts with coworkers from the comfort of their own home. The benefits of remote working are huge, allowing workers greater flexibility and a far better work–life balance. Overall, this has resulted in a much higher productivity and increased motivation, often leading to better and more creative approaches to design problems.

Designers have been released from old constraints with new tools, managers must take on new business practices, designers must understand the power at their disposal and marketing personnel must be aware of their new found ability to react quickly to market changes. These are the new rules of prototype manufacturing.

When looking to create a product prototype it is important to understand what kind of manufacturer you are looking for; taking into account manufacturing method, budget, lead time and the purpose of your prototype. Gaining a basic understanding of these requirements will narrow down your search and focus your efforts. Any machine shop can technically manufacture machined parts according to a print; however, the challenge is in finding a machine shop or contract manufacturer who has the right machinery, quality, lead-time, and prices. Below are three of the most critical points to address in choosing your prototype manufacturer:

Companies that specialize in building prototypes can either manufacture in-house or sub-contract out manufacturing of parts and only focus on supply chain management and assembly. At the higher end of these sub-contracting services are vertically integrated engineering firms that will help with design and even offer marketing and financial services. At the other end of the spectrum are manufacturers that specialize in their respective processes with little to no experience outside of that niche.

Though the cost savings associated with sourcing individual components may seem large on paper, it is important to address the multitude of hidden costs. The first of which is the time investment required to effectively identify a contract manufacturer and develop a functional relationship. Even the quoting process can be time consuming and costly, requiring multiple emails and phone calls to conclusively correlate the designers needs and manufacturers responsibilities.

Added costs to sourcing individual parts rather than working with a centralized contract manufacturer (CM) also include hardware storage, assembly time, quality control, training, and logistics. Quantifying these costs for in-house assembly is an important step in identifying the most efficient and cost effective process for your prototype. For example, MACABItech originally subcontracted a small manufacturer to both cut and assemble the parts for a rolling dolly. The subcontractor was given drawings and specifications for the entire assembly, and asked to install all parts except for the castors. After numerous attempts to address shortcomings in the manufacturing process, MACABItech chose to pivot from out-sourcing the entire assembly to focusing the manufacturers efforts on woodworking, which is what they did best. Paradoxically enough, this reduced cost in assembly time as well as in purchase costs; MACABItech had previously needed to disassemble, qualify, and then re-assemble each unit. The revised process permitted a more streamlined workflow, saving 30% of the assembly costs each dolly.

The vision you have of how your components should look and what the manufacturer thinks is acceptable might be very different. That is why there is a significant amount of time and effort spent on building a relationship and understanding with the people who will be making your prototype.

Cost factors include set up time, tools, materials and run time. Economies of scale are a critical factor, as the manufacturer might be making your part that one and only time, so the price tag will be significantly higher the first time than once you go to production. Some manufacturers will often resist giving a quote until they have made one part and understand what producing such part entails. Others will overquote, with the understanding that manufacturing a new component takes time, communication, and inevitable trial and error.

The main way to understand if a machine shop will meet your project requirements is to establish a line of communication with them, or better yet, visit their manufacturing facility. Shops usually have a production manager or an engineer who can assess your prints or 3D models and tell you if they can manufacture the parts. You will see the difference when someone is engaged and asking the right questions. The quality of the feedback you receive largely depends on the people who work there. Note that not all are focused on providing engineering feedback. Some shops are set up to just manufacture high quantities of simple parts. The places that specialize in prototyping will usually have someone who is more in tune with the design decisions behind a parts features. This kind of expertise usually comes with a higher price tag. Be on the lookout for manufacturers that do not question or try to understand your design decisions, and ensure that your design data (drawings and CAD files) leave nothing up for interpretation.