- USABoston

- UKGlasgow

There’s more to making a product than meets the eye. We consolidate product design, manufacturing and technical development into one seamless process that delivers the results you need to make your company a success. The formula for design at MACABItech focuses on manufacturability and logical approaches to production. No matter the size of your company or project we pride ourselves on being a true partner to our customers.

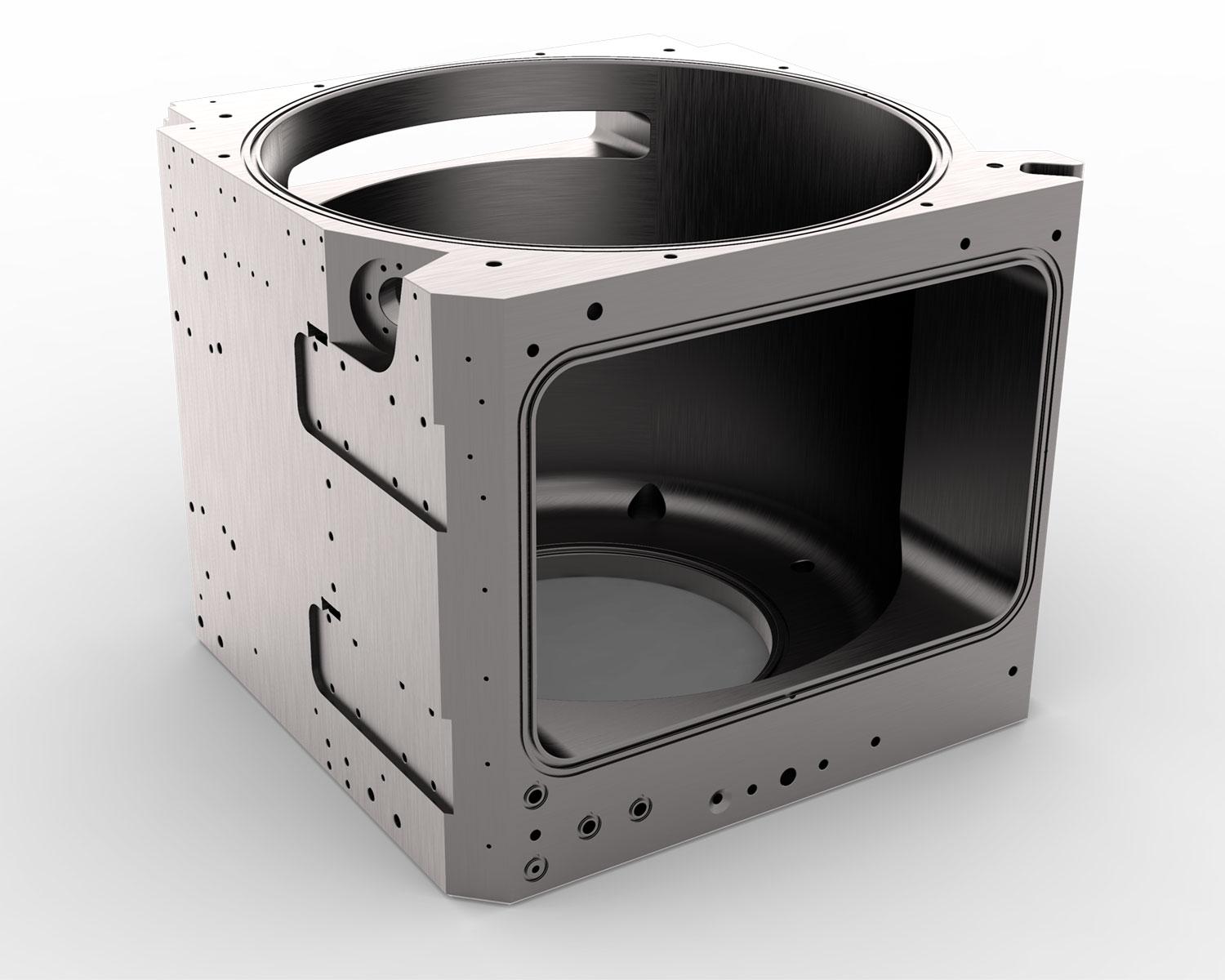

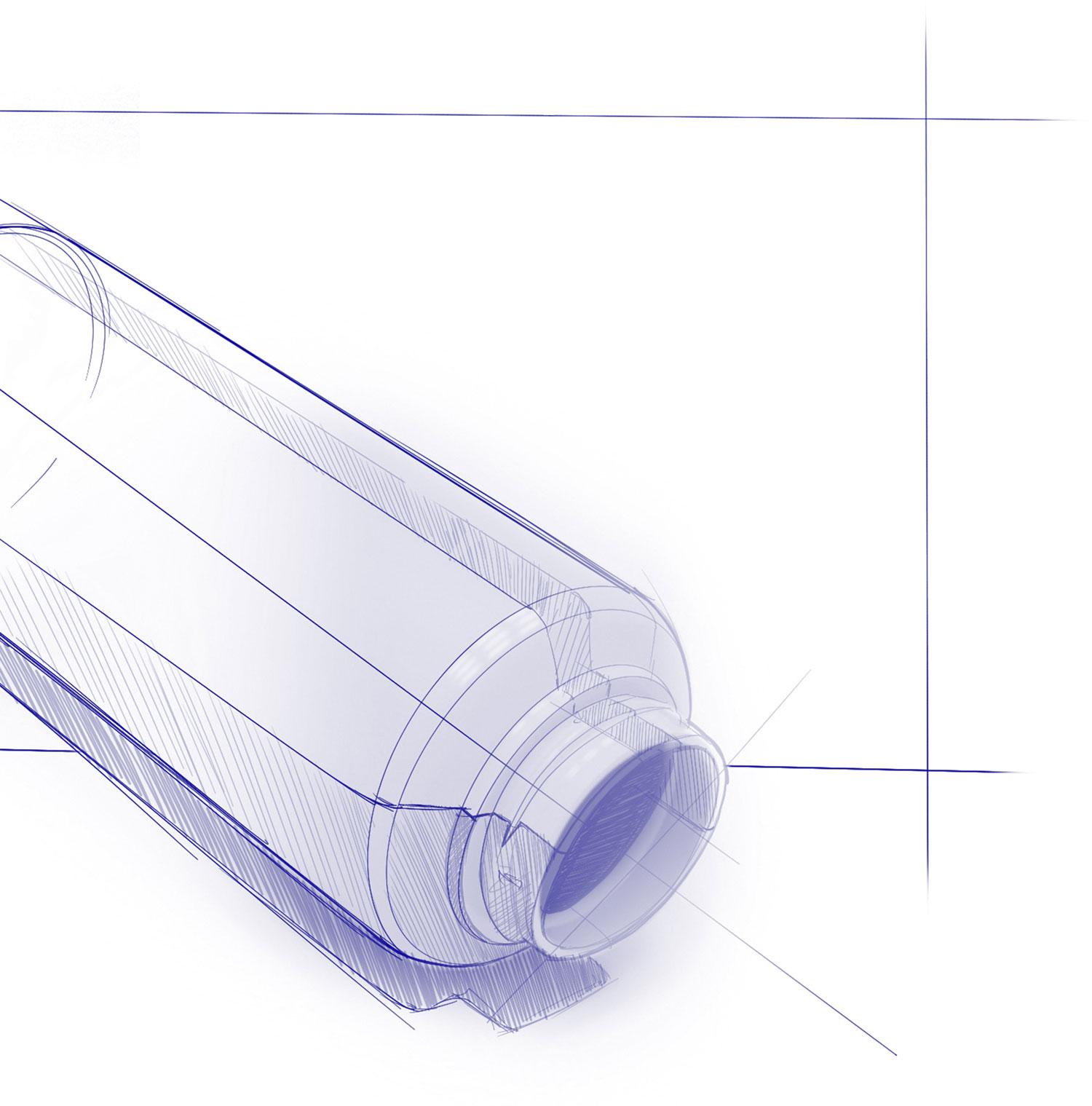

You have the idea and now it’s time to make it a reality. Our product designers specialize in building full CAD models and animating mechanical events so you can fully conceptualize the best approach to your project and understand the costs. From simple 3D models to complex parameterized mechanical assemblies, we design for manufacturing (DFM) at every step of the way.

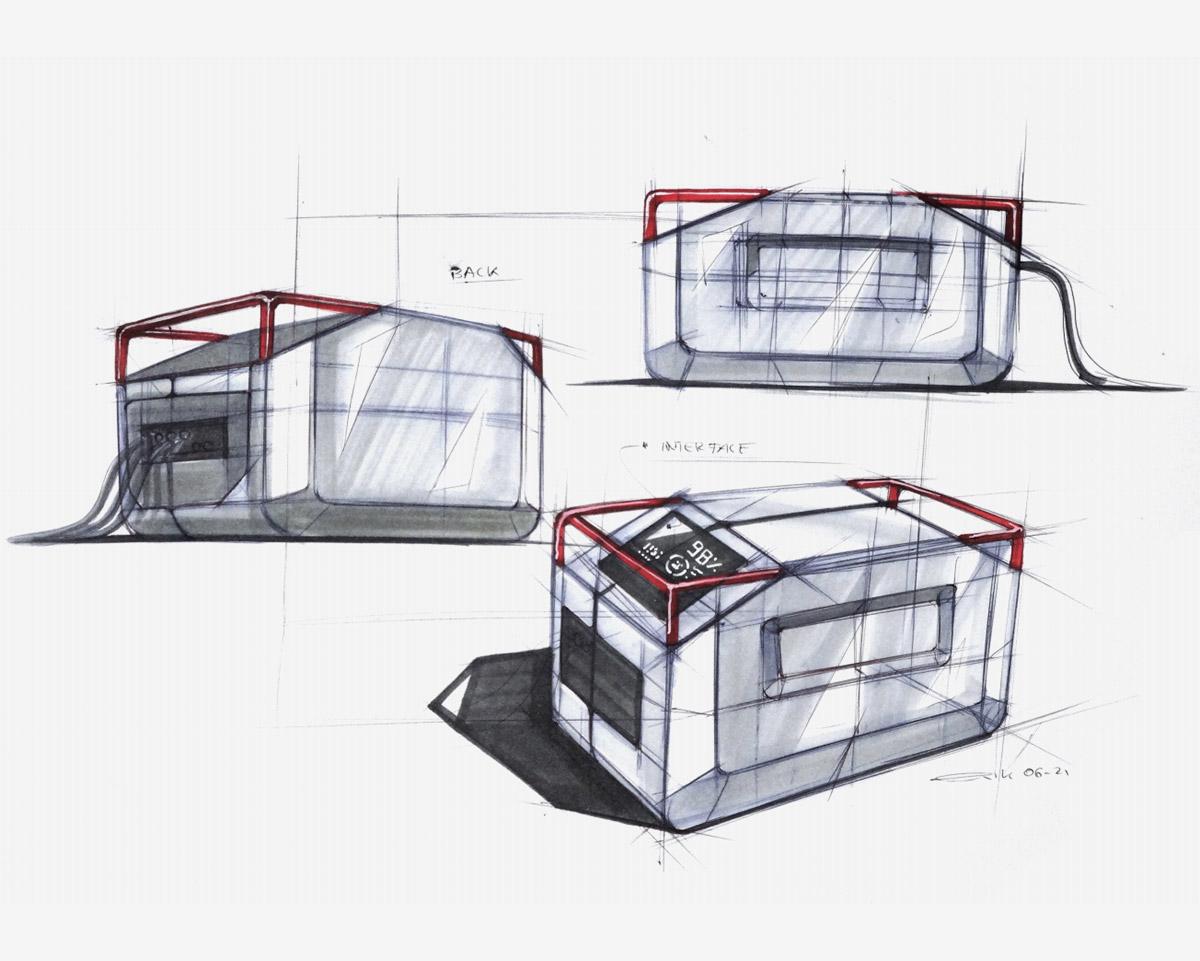

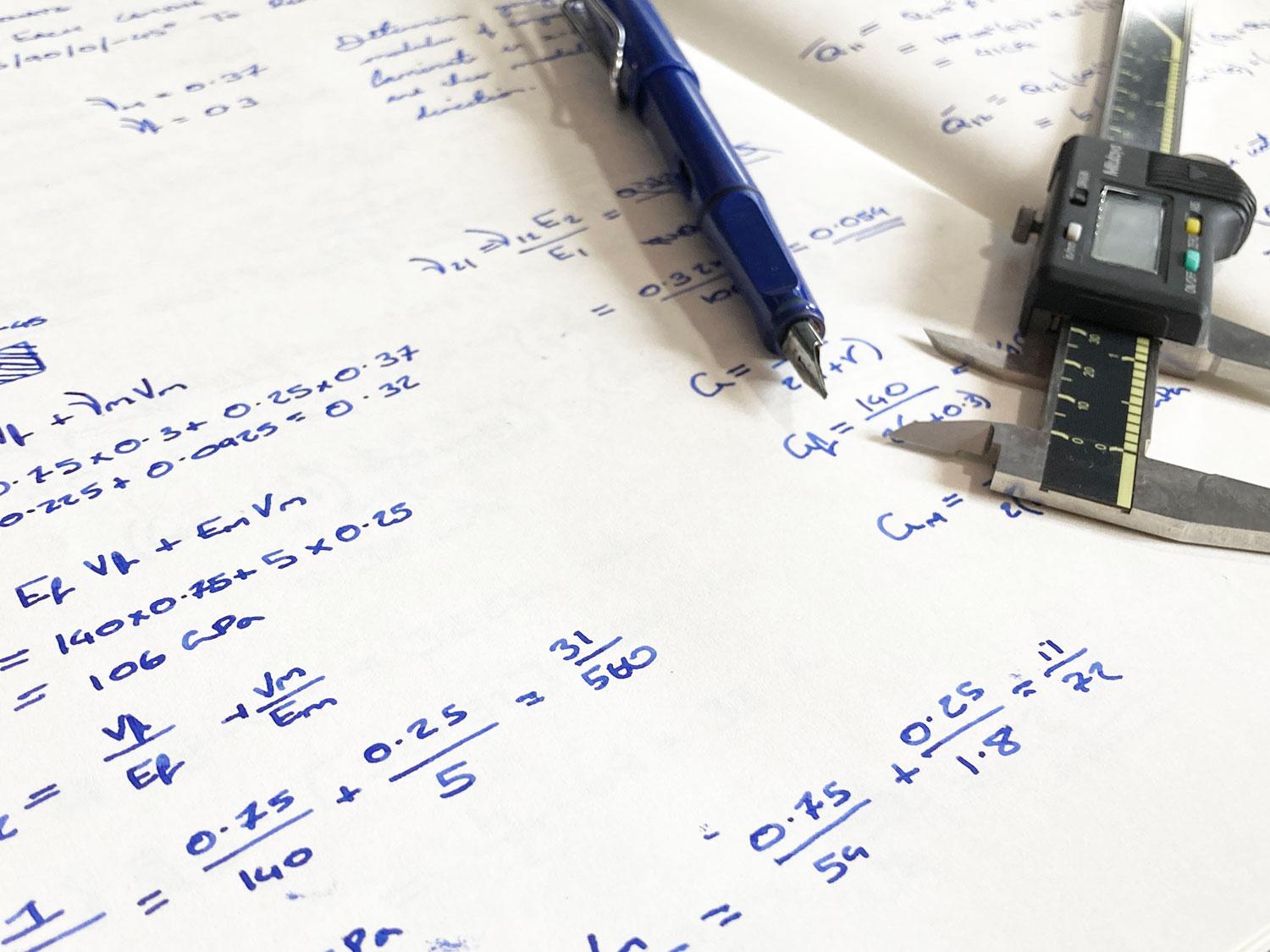

Our expertise cover the full design cycle and include: ideation and visualization, engineering calculations, Finite Element Analysis (FEA), Design for Manufacture (DFM), Computer-Aided Design and Manufacture (CAD/CAM). We minimize the number of iterations to develop your product, saving you time and money.

The best techniques and supplies aren’t always in your workshop. Our processes and partnerships with a network of domestic and international manufacturers and suppliers allow us to build any product using the newest methodologies and machinery. With our deep knowledge of CNC machining and additive manufacturing, computer-aided manufacturing and injection molding for high volume plastic parts, we work with exactly what you need to reach your next milestone.

MACABItech uses Siemens NX, the industry leader in CAD/CAM software to execute on the most complicated projects that require control over the finest details of design, manufacturing, and data management.

NX CAM is capable of optimizing and fine-tuning CNC machine tool paths with the highest level of precision and flexibility. NX leverages high-speed multi axis machining, automated shop-floor documentation, and a seamless modelling/manufacturing environment. This gives MACABItech the ability to deliver a complete manufacturing process.

The modelling environment is the industry benchmark for parametric design, allowing external requirements tables to drive 3d outputs. Assemblies and part files coexist in the same interface, with information management that permits the level of detail required to handle assemblies of thousands of parts effectively. In combination with this precision, synchronous modelling tools provide the critical capability to rapidly iterate on design concepts.

“NX is the most powerful, flexible, and innovative product development solution in the industry, NX for Design has the features, performance, and capabilities to help you get product to market faster than ever before.”

Fusion 360 is a disruptive cloud-based 3D modelling, CAD, CAM, CAE software for product design and manufacturing. This allows MACABItech to work collaboratively across multiple time zones, in the field and in the boardroom to deliver our clients what they want, when they need it.

The flexibility of Fusion 360s parametric modelling environment allows our designers and engineers to produce functional, aesthetic, and realizable designs in a time critical manner.

For small batch, cost sensitive prototype runs, we use Fusion 360s integrated CAD + CAM functionality to deliver manufacturable results quickly and efficiently. The NASTRAN based computer aided engineering (CAE) tools inside of Fusion permit us to assess the viability of designs before cost intensive prototyping takes place. Animation capabilities allow MACABItech to display product assembly mechanisms, create work instructions, and display functionality to drive innovative design decisions.

See what it takes to develop your idea with a free consultation with our team.