- USABoston

- UKGlasgow

CASE STUDY

CASE STUDY

How Understanding Design for Manufacturing and Assembly Saved Macris Industries Multiple Prototype Iterations.

Macris Industries is a marine product development company specializing in durable and submersible luxury lighting systems.

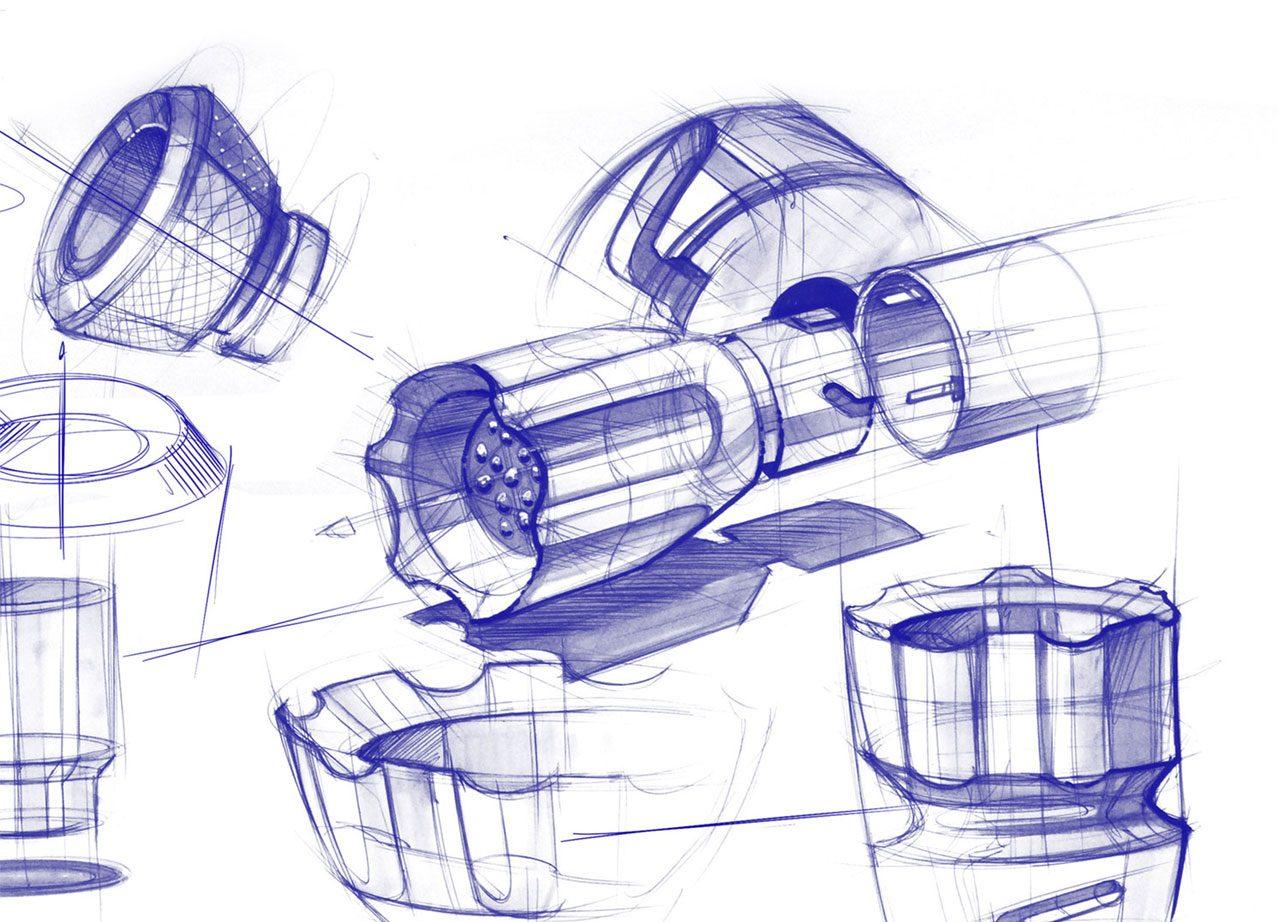

The Pico is an aluminum heatsink and housing for a waterproof mini LED spotlight.

Harrison Macris

To integrate custom LED hardware into a robust, easy-to-maintain housing using similar technology to their existing lighting solution in a new package.

Initially, MACABItech was approached to help with identifying the right manufacturer for the product. However, during the design process, the Pico was developed into several different variants after MACABItech successfully sourced the initial prototype. Drawing from our manufacturing experience MACABItech updated the latest versions of the design with a focus on manufacturability, limiting further revisions and reducing overall production costs.

After receiving 3D models from Macris Industries for a new version of the Pico, MACABItech completed a holistic manufacturing review process. This in-depth investigation revealed Macris Industries had specified a feature in their model with geometry that was not manufacturable using traditional CNC milling and turning machines. Almost undetectable to the eye, MACABItech’s manufacturing review revealed this mistake that would have more than doubled the cost of the part. Once rectified using MACABItech’s in house design services, the part could easily be manufactured in a standard 4-axis mill-turn, greatly reducing the production cost originally associated with the product.

Client: Macris Industries DFMA

Company type: Start-up

Milestone type: Pre-production prototype

Location: Mystic, CT

Industry: Marine Product Development

See what it takes to develop your idea with a free consultation with our team.