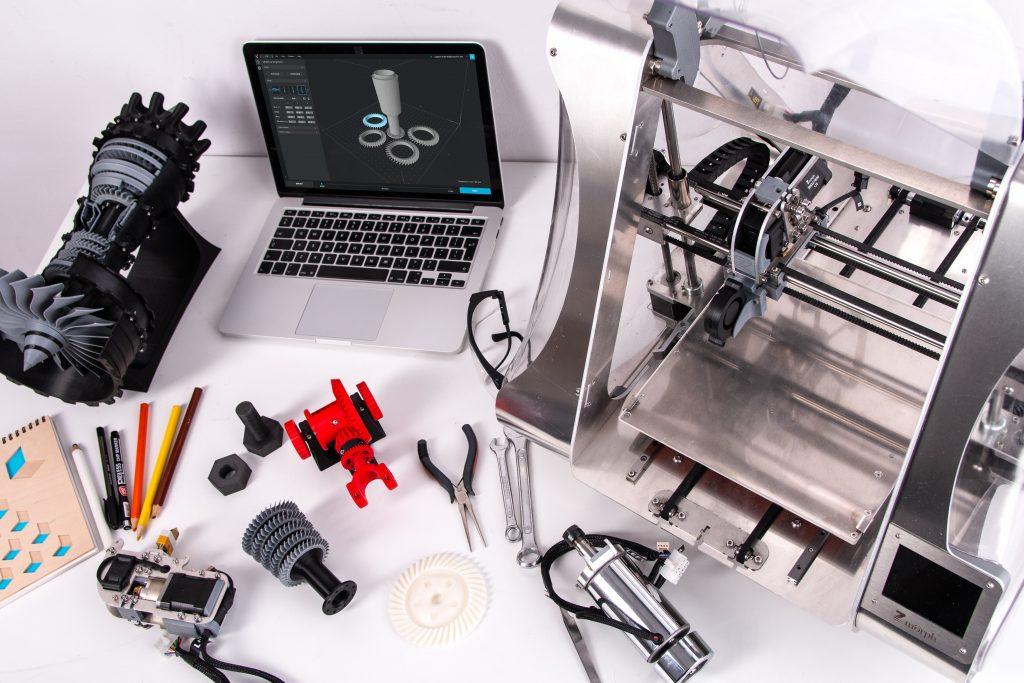

When looking to create a product prototype it is important to understand what kind of manufacturer you are looking for; taking into account manufacturing method, budget, lead time and the purpose of your prototype. Gaining a basic understanding of these requirements will narrow down your search and focus your efforts. Any machine shop can technically manufacture machined parts according to a print; however, the challenge is in finding a machine shop or contract manufacturer who has the right machinery, quality, lead-time, and prices. Below are three of the most critical points to address in choosing your prototype manufacturer:

What are the costs of in-house assembly vs contract-manufacturing?

Companies that specialize in building prototypes can either manufacture in-house or sub-contract out manufacturing of parts and only focus on supply chain management and assembly. At the higher end of these sub-contracting services are vertically integrated engineering firms that will help with design and even offer marketing and financial services. At the other end of the spectrum are manufacturers that specialize in their respective processes with little to no experience outside of that niche.

Though the cost savings associated with sourcing individual components may seem large on paper, it is important to address the multitude of hidden costs. The first of which is the time investment required to effectively identify a contract manufacturer and develop a functional relationship. Even the quoting process can be time consuming and costly, requiring multiple emails and phone calls to conclusively correlate the designers needs and manufacturers responsibilities.

Added costs to sourcing individual parts rather than working with a centralized contract manufacturer (CM) also include hardware storage, assembly time, quality control, training, and logistics. Quantifying these costs for in-house assembly is an important step in identifying the most efficient and cost effective process for your prototype. For example, MACABItech originally subcontracted a small manufacturer to both cut and assemble the parts for a rolling dolly. The subcontractor was given drawings and specifications for the entire assembly, and asked to install all parts except for the castors. After numerous attempts to address shortcomings in the manufacturing process, MACABItech chose to pivot from out-sourcing the entire assembly to focusing the manufacturers efforts on woodworking, which is what they did best. Paradoxically enough, this reduced cost in assembly time as well as in purchase costs; MACABItech had previously needed to disassemble, qualify, and then re-assemble each unit. The revised process permitted a more streamlined workflow, saving 30% of the assembly costs each dolly.

What are some critical cost factors to consider in small-scale production and prototype manufacturing?

The vision you have of how your components should look and what the manufacturer thinks is acceptable might be very different. That is why there is a significant amount of time and effort spent on building a relationship and understanding with the people who will be making your prototype.

Cost factors include set up time, tools, materials and run time. Economies of scale are a critical factor, as the manufacturer might be making your part that one and only time, so the price tag will be significantly higher the first time than once you go to production. Some manufacturers will often resist giving a quote until they have made one part and understand what producing such part entails. Others will overquote, with the understanding that manufacturing a new component takes time, communication, and inevitable trial and error.

What questions should be asked to identify a viable supplier or contract-manufacturer?

The main way to understand if a machine shop will meet your project requirements is to establish a line of communication with them, or better yet, visit their manufacturing facility. Shops usually have a production manager or an engineer who can assess your prints or 3D models and tell you if they can manufacture the parts. You will see the difference when someone is engaged and asking the right questions. The quality of the feedback you receive largely depends on the people who work there. Note that not all are focused on providing engineering feedback. Some shops are set up to just manufacture high quantities of simple parts. The places that specialize in prototyping will usually have someone who is more in tune with the design decisions behind a parts features. This kind of expertise usually comes with a higher price tag. Be on the lookout for manufacturers that do not question or try to understand your design decisions, and ensure that your design data (drawings and CAD files) leave nothing up for interpretation.

- Make sure you have the answers to the following questions clearly defined when picking out a supplier or contract manufacturer for your prototype.

- What’s the objective of your prototype?

- Are you simply testing a concept or developing a pre-production unit?

- Are you making the first product that will be used to impress investors?

- Do aesthetics matter?

- What kind of material are you using?

- What quantities of parts will you be manufacturing?

- What is the maximum lead time you can accept?

- What quality standards should your suppliers be conforming with, if any (AS9100, ISO9001, etc)?

- What equipment should your contract manufacturing partner have access to?

- Does your prototype include more than one kind of material?

- Will you assemble the prototype yourself?

- Are you building relationships with manufacturers from the beginning knowing that they will manufacture your production quantities?

- Which two take priority: budget, quality or lead time?